Differences between chip heater and traditional tube heater:

Chip Heater | Tube Heater |

Direct and fast | Indirect and slow |

Heating Efficiency--98.9% | 81% Heating Efficiency--81% |

service life --20,000 hours | service life --3,000 hours |

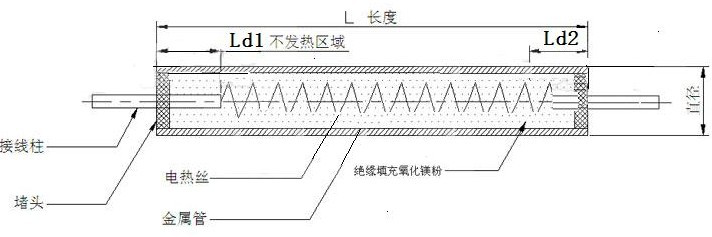

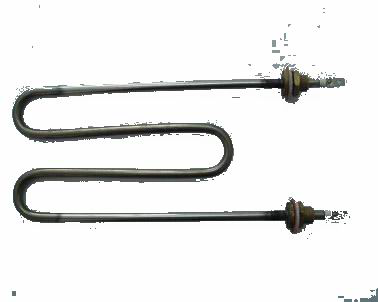

Traditional working principle

Traditional tube heater is made by putting the heating wire into a seamless metal pipe (carbon steel pipe, titanium, stainless steel pipe, copper pipe) and filling the gap with magnesium oxide powder of good thermal conductivity and insulation and then shrinking the whole tubes into various type of shapes to meet our customers’ needs. When an electric current passes through the high temperature resistance wire, the generated heat spreads the metal surface through magnesium oxide powder and then passes to the heated or the air, achieving the purpose of heating. Traditional heating works directly and slowly with only 81% heating efficiency.

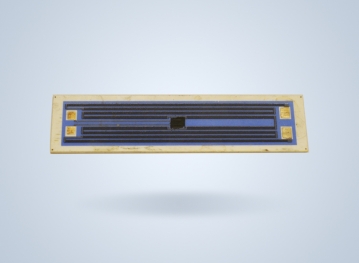

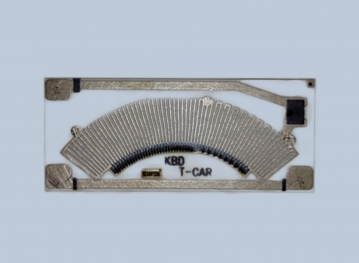

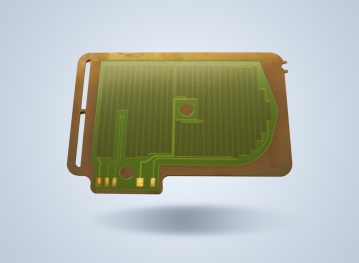

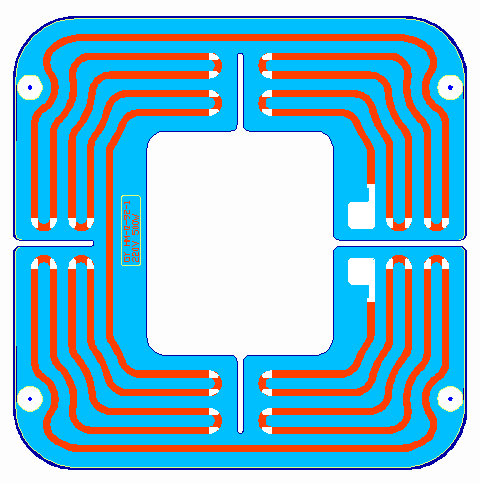

Working principle of chip heater

Thick film that generates the heat is printed on the substrate directly. Its low thermal mass ensures a quick response, which helps the heating efficiency up to 98.9% and the service life can last more than 20,000 hours.

Features of chip heater:

◎More Power-saving

30% more power saving, intelligent heating, no power consumption in heat preservation, more efficiency in heating (98.9%).

◎More Environmental-Friendly

Perfect and eco-friendly transformation from electricity to power no carbon emission.

No incrustation, clear hot water .

◎More Safe

Aerospace technology assures better security with multi-layer insulation protection whose insulation performance is 250 times that of the electric wire.

◎More Efficient

The heating speed of the chip is 5 times faster than that of the heating wire, and the temperature of heating body can reach to 150-300 degrees by 3 seconds.